Partner with WJ Group and discover how our proven solutions can shape the success of your project.

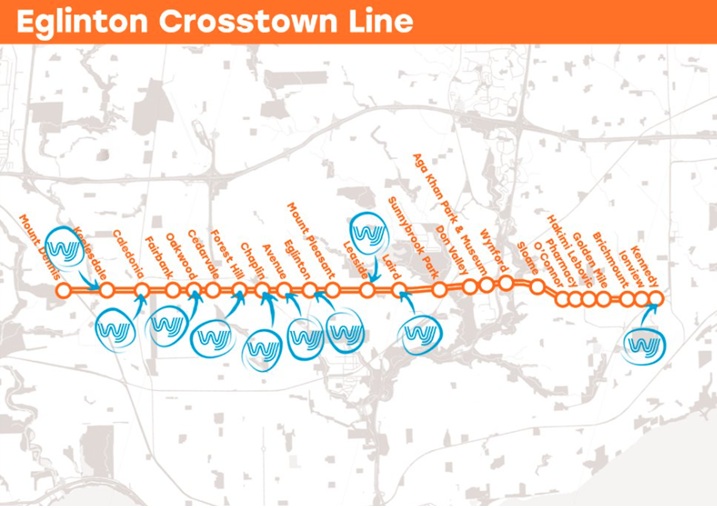

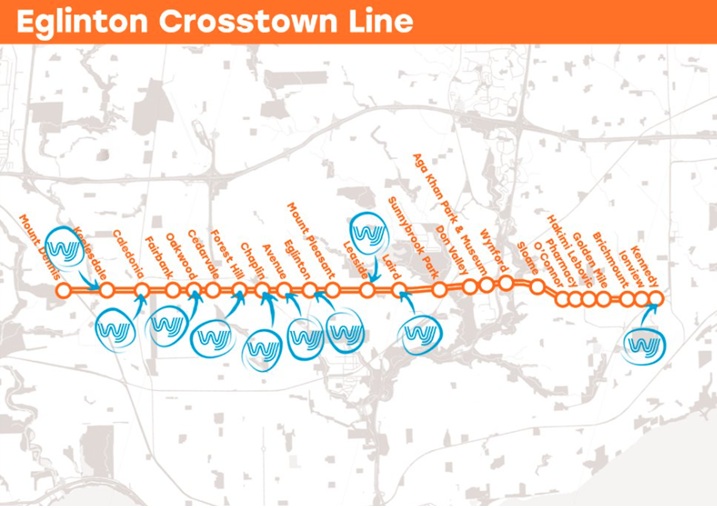

The Eglinton Crosstown Light Rail Transit (ECLRT) project is Toronto’s most ambitious upgrade to its mass transit subway system since Line 4 (Sheppard) opened in 2002. Designed to improve east-west connectivity across the city, and reduce travel time along Eglinton Avenue by 80%, the line is 19 kms long and includes 25 stations and stops. The underground section, approximately 10 km between Keele and Laird stations, would be the most demanding to construct – the tunnelling would be completed by traditional tunnel boring machine (TBM) techniques but the station caverns for Oakwood, Avenue, Laird and Bayview would be up to 300 m long, up to 30 m wide and up to 30 m below ground level, and were to be constructed by mining and sprayed concrete lining (SCL) to avoid major road closures and disruption to one of Toronto’s main east – west arteries. SCL requires the ground to be fully dewatered and depressurised and in Toronto’s water bearing, stratified, glacial subsoil comprising layered clays, silts and sands, this was one of the main challenges facing the contractor, a joint venture comprising leading Canadian contractors Ellis Don and Aecon and Spanish tunnelling specialist Dragados.

WJ had recently successfully delivered solutions for similarly complex dewatering problems in stratified low permeability soils for Dragados’ SCL work on London’s Crossrail project and were invited to tender for Eglinton’s Segment 4, comprising 4 of the central stations.

WJ’s innovative proposals included vertical and inclined wells drilled from the surface, ejector wells and ejector pumping systems installed within station entrance shafts, inclined and vertical wellpoints installed through the base and sides of the completed TBM tunnel, and sacrificial ejector wells and wellpoints installed in stages during the SCL process. WJ would undertake the works using compact drilling machinery (5 to 10 tonnes) and compact pumping solutions which would require very small footprints – essential on the extremely restricted construction sites. These solutions contrasted with the traditional approach to dewatering in Toronto which was undertaken by very large drilling machines (30 tonnes), in conjunction with huge space requirements at the surface for pumps, pipes and tanks.

The subsequent contract award was one of the largest ever placed with WJ. Site works commenced in mid 2016 and during the peak of installation WJ were operating 7 drilling rigs along Eglinton Avenue. As the results of WJ’s designed approach and achievement of time and drawdown targets became clear, stations which had previously been planned to be undertaken using alternative methods, asked us to provide solutions. From the initial contract at four stations, WJ went on to provide dewatering services at ten stations and several intermediate shafts. WJ is now the leading dewatering provider for underground infrastructure in Toronto.

WJ Group have completed many projects globally. Click on the links below to learn more about what we do.

Are you ready to see what else our vision can bring to your projects? Why not speak to our team of groundwater experts today?