Partner with WJ Group and discover how our proven solutions can shape the success of your project.

As part of the Crossrail project, which established the first direct rail connection across central London—from Paddington in the west to Abbey Wood in the southeast—a new tunnel was required beneath the River Thames between North Woolwich and Plumstead.

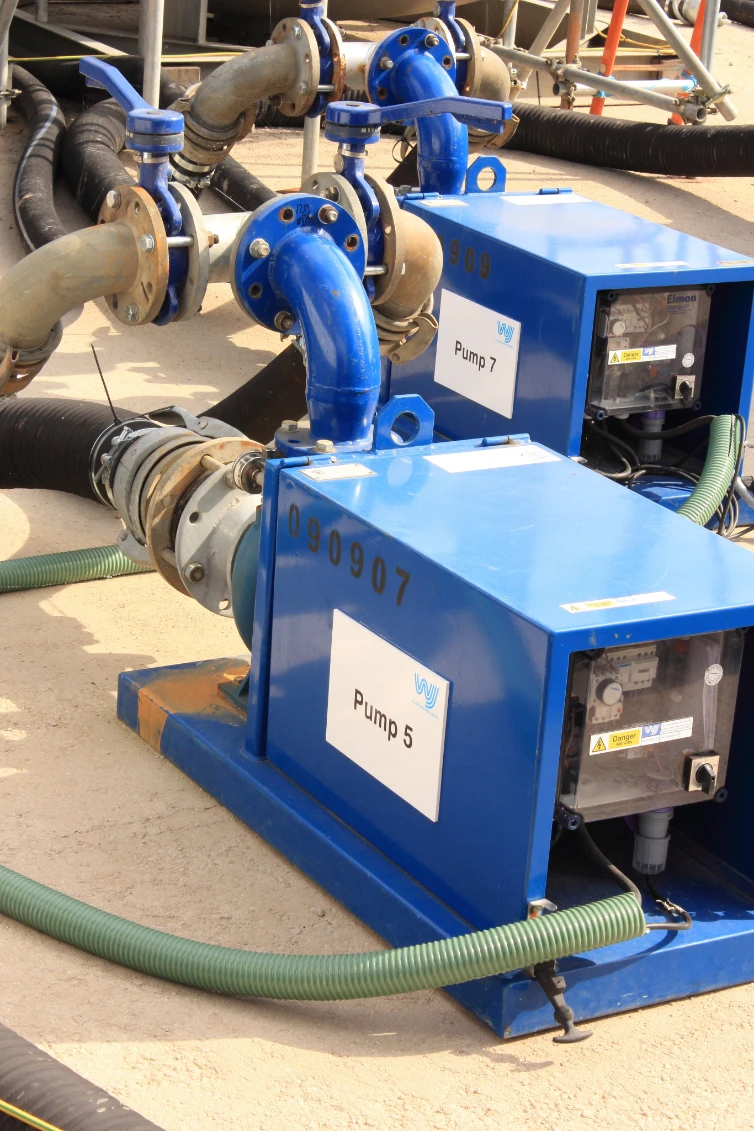

The North Woolwich portal was constructed within a box structure up to 25 m deep, comprised of diaphragm walls and secant piles which to an extent provided a hydraulic cut off to the highly permeable River Terrace Gravels. However the underlying strata was Thanet Sand (a very fine, silty sand) and chalk (a soft fissured rock) with a groundwater table 5 m below ground level. Groundwater pumping tests and 3D modelling, carried out by WJ, had shown that total abstraction rates to provide the contractor, a joint venture between John Murphy and Hochtief, would be up to 150l/sec.

Located in east London and surrounded by sites with over 150 years of industrial legacy, including the former Beckton Gasworks —once the largest coal gasworks in the world—just 2 km away, there were concerns that historical hydrocarbon contamination could be mobilised within the chalk aquifer, posing a risk to both environmental compliance and construction stability.

Using advanced 3D groundwater modelling, the expected dewatering discharge rate was calculated at up to 150 litres per second, with direct discharge planned to the River Thames. Given the critical nature of the excavation and tunnelling works, any interruption to dewatering would have had catastrophic consequences for portal stability and the overall construction programme.

To mitigate this risk, WJ designed and installed a contingency treatment plant capable of handling the full discharge volume. This ensured that, in the event of contamination, only clean water would be released into the Thames.

Fortunately, while the system was regularly operated and tested to ensure reliability, no contamination levels exceeded environmental compliance limits. Upon completion of tunnelling and portal construction, the dewatering system and treatment plant were successfully demobilised.

This would be the 5th tunnel under the River Thames successfully dewatered by WJ.

WJ Group have completed many projects globally. Click on the links below to learn more about what we do.

Are you ready to see what else our vision can bring to your projects? Why not speak to our team of groundwater experts today?