Partner with WJ Group and discover how our proven solutions can shape the success of your project.

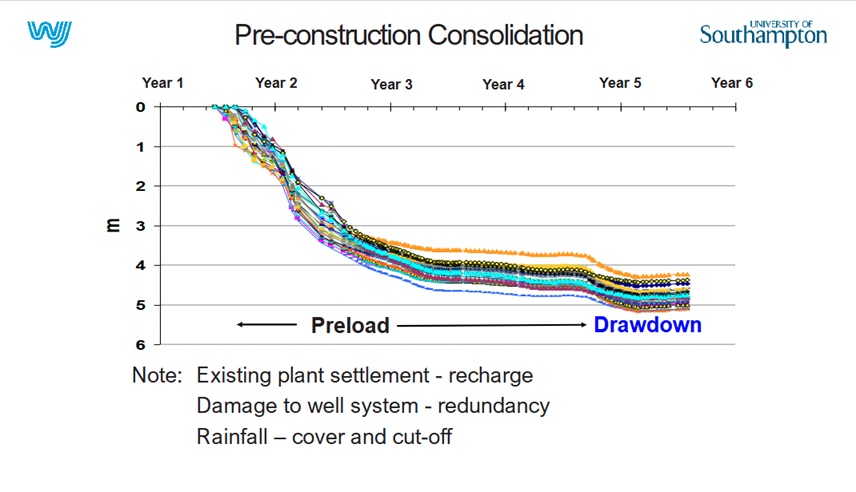

The construction of a major gas to liquids plant adjacent to an existing gas processing plant was planned in the Niger delta. The high foundation loads and low lying soft, normally consolidated nature of the substrata soils required a novel approach involving consolidation of the ground using a combination of sand preload, vertical PVDs (prefabricated vertical drains) and groundwater lowering. WJ designed and carried a pumping test to investigate the hydrogeological characteristics of the substrata and the feasibility of the groundwater lowering.

The project involved the mobilisation of a 2 person drill crew, a Cable Percussion drilling rig and tooling, a range of pumping kit and monitoring equipment, and engineers and technicians to the remote site. For personnel, this required a transfer through Lagos airport and then a 3 hour flight on a light plane. Once there, our staff had to with the incredibly challenging working conditions of a tropical mangrove swamp in a remote location. Despite the challenges, the wells and piezometers were successfully installed, and a model pumping test was carried out.

The dewatering scheme was subsequently designed and installed by others but failed to achieve the target drawdown and induced settlement.

WJ were re-engaged by the client to undertake a design and performance review of the installed dewatering and recharge scheme. This included full review of the system design documents, site records together with on site testing and performance monitoring. WJ then developed and calibrated a 3D time dependent numerical seepage model of the site to investigate a range of options to upgrade the system. These options were discussed with the client and the project team agreed a remediation strategy to overcome the shortcomings in the dewatering system capacity which included:

WJ provided detailed specifications for the necessary system upgrades and subsequently provided site supervision of installation and ongoing performance monitoring. The remediation measures proved highly effective with the target drawdown achieved and maintained for the 6 month period required to provide the necessary preload and consolidation. Construction of the GTL plant proceeded as planned following shut down and decommissioning of the dewatering system.

WJ Group have completed many projects globally. Click on the links below to learn more about what we do.

Are you ready to see what else our vision can bring to your projects? Why not speak to our team of groundwater experts today?